ESD Epoxy

A specialized electrostatic dissipative coating system engineered to safely control and discharge static electricity in sensitive environments.

Protect What Matters Most

Key Benefits

ESD epoxy flooring (Electrostatic Dissipative epoxy) is a specialized resinous coating system designed to control and safely dissipate static electricity. In environments where sensitive electronics, volatile materials, or precision equipment are present, uncontrolled static discharge can cause product damage, data loss, equipment malfunction, or even safety hazards. An ESD epoxy system incorporates conductive or dissipative materials within the coating structure, allowing static electricity to flow safely through the floor and into a properly grounded system rather than building up on surfaces or personnel.

These systems are most commonly used in electronics manufacturing facilities, laboratories, data centers, pharmaceutical plants, clean rooms, aerospace environments, and areas where combustible materials are handled. Even a small electrostatic discharge can damage microchips or sensitive circuit boards, resulting in costly defects. ESD flooring helps maintain a controlled static environment by keeping electrical resistance within a specified range, typically measured in ohms to meet industry standards for electrostatic dissipation.

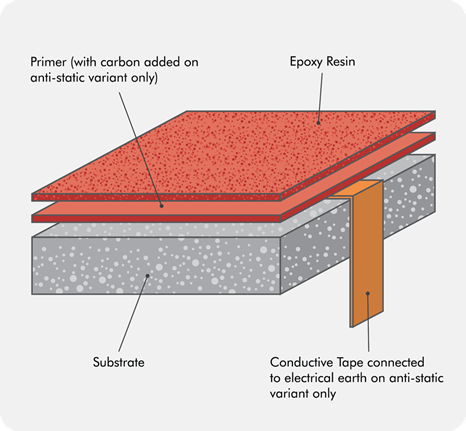

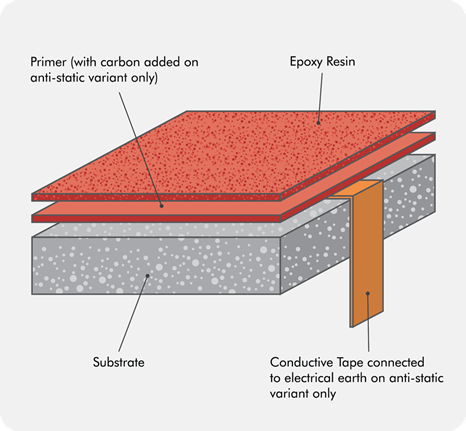

An ESD epoxy system typically consists of multiple layers, including a primer, a conductive base coat, embedded copper grounding strips, and a specialized dissipative topcoat. The copper grounding grid is connected to an approved grounding point, creating a continuous pathway for static energy to discharge safely. The finished surface remains seamless, durable, and easy to clean, while maintaining consistent electrical properties across the entire floor area. Proper installation and testing are critical to ensure the system performs within the required resistance range.

Beyond static control, ESD epoxy floors still provide the durability and chemical resistance expected from high-performance resinous coatings. They resist abrasion, moisture, and common industrial contaminants while maintaining a smooth, professional appearance. When installed over properly prepared concrete with the correct surface profile and grounding configuration, an ESD epoxy system offers both structural durability and controlled electrostatic performance, making it an essential solution for high-tech and precision-driven environments.

Key Benefits

ESD Epoxy Features

Static Dissipation Control

Conductive materials within the coating safely channel static electricity through the floor to a grounded system, preventing dangerous discharge.

Copper Grounding Grid

Embedded copper strips connected to an approved grounding point create a continuous pathway for safe electrostatic discharge across the entire floor.

Precision Environment Ready

Maintains consistent electrical resistance within industry-standard ranges, protecting sensitive electronics, data, and precision equipment.

Ready to Get Started?

Contact us today for a free consultation and estimate on your ESD epoxy flooring project.