The Foundation of Every Successful Epoxy Floor

Ask any experienced epoxy flooring professional what the most important step in any installation is, and the answer will always be the same: surface preparation. The performance, adhesion, and longevity of an epoxy coating system are directly determined by how well the concrete substrate is prepared before the first drop of resin is applied.

Surface preparation is not glamorous. It is loud, dusty, and labor-intensive. But it is the difference between a floor that lasts 15–20 years and one that peels, bubbles, or delaminates within months. Cutting corners on preparation is the single most common cause of epoxy floor failure.

What Happens Without Proper Preparation

When epoxy is applied over improperly prepared concrete, the coating cannot achieve a mechanical bond with the substrate. The result is predictable and often dramatic:

Delamination: The coating separates from the concrete in sheets or large sections. This typically occurs within the first few months to a year and is almost always caused by inadequate surface profiling or contamination on the slab.

Bubbling and Blistering: Moisture trapped beneath the coating creates vapor pressure that pushes the epoxy away from the slab. This is caused by failing to test for and address moisture vapor transmission before coating.

Peeling and Flaking: Localized adhesion failure where the coating lifts at edges, around cracks, or in high-traffic areas. Often caused by oil contamination, residual sealers, or insufficient surface roughness.

Premature Wear: Coatings applied over smooth or glazed concrete wear through quickly because the epoxy has no mechanical grip on the substrate. High-traffic areas show bare concrete within months.

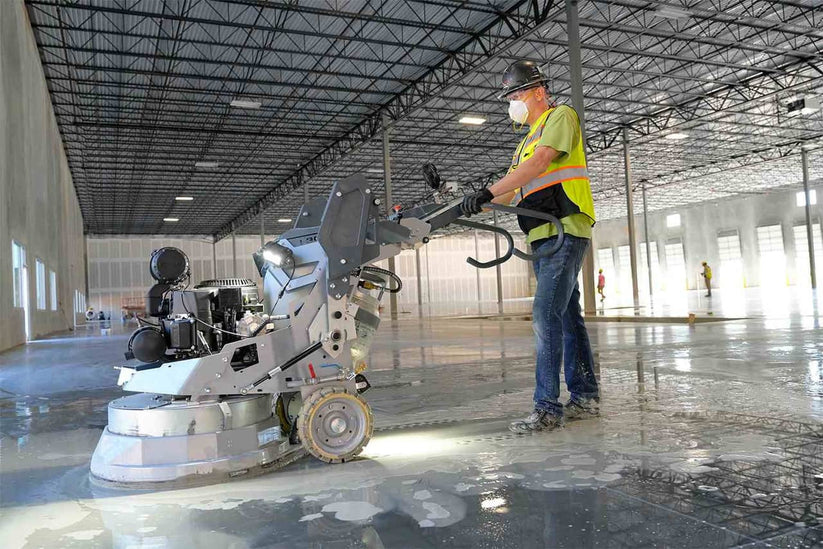

Diamond Grinding: The Gold Standard

Professional epoxy installers use industrial diamond grinding equipment to prepare concrete surfaces. Diamond grinding involves using rotating discs embedded with industrial diamonds to mechanically abrade the concrete surface. This process achieves three critical objectives:

1. Surface Profile: Grinding creates a rough, open-pored surface texture (typically ICRI CSP 2–3) that allows the epoxy to penetrate and bond at a molecular level. Without this profile, the coating sits on top of the concrete rather than bonding to it.

2. Contaminant Removal: Grinding removes surface contaminants including dirt, oils, previous coatings, paint, adhesive residue, and laitance (the weak, chalky layer on the surface of cured concrete). These contaminants act as bond breakers that prevent proper adhesion.

3. Pore Opening: The grinding process opens the pores of the concrete, allowing the primer coat to penetrate into the substrate. This penetration creates a mechanical interlock between the concrete and the coating system.

Why Not Acid Etching?

Many DIY epoxy kits recommend acid etching — applying muriatic or phosphoric acid to the concrete to roughen the surface. While acid etching can technically create some surface profile, it is unreliable and inconsistent for several reasons:

Diamond grinding is universally recognized by coating manufacturers and industry professionals as the superior preparation method for resinous flooring systems.

Moisture Testing and Mitigation

Concrete is porous, and all concrete slabs contain some degree of moisture. When the moisture vapor transmission rate exceeds the coating system's tolerance, the vapor pressure beneath the coating can cause delamination, bubbling, and adhesion failure.

Professional installers test for moisture using the industry-standard method:

Relative Humidity Test (ASTM F2170): Measures the internal relative humidity of the concrete slab using probes drilled into the slab. This provides an accurate picture of the slab's overall moisture condition. Most coating manufacturers specify a maximum RH of 75–80%.

If moisture levels exceed the system's tolerance, a moisture mitigation system is applied before the epoxy coating. These systems use specialty primers or membranes that block moisture vapor transmission while still allowing the epoxy to bond to the surface.

Crack and Defect Repair

Before any coating is applied, all cracks, spalls, divots, and expansion joints must be evaluated and repaired:

Crack Repair: Cracks are routed (widened) and filled with flexible or rigid repair materials depending on whether the crack is active (still moving) or dormant. Properly repaired cracks will not telegraph through the finished floor.

Spall Repair: Spalls (areas where concrete has chipped or broken away) are filled with epoxy mortar or patching compound to restore a smooth, level surface.

Joint Treatment: Expansion joints and control joints may be honored (left as functional joints) or filled depending on the joint type and the coating system. Improperly treated joints can crack through the coating as the slab moves.

The Professional Difference

This is where the gap between professional installation and DIY becomes most apparent. A professional epoxy flooring contractor invests in:

This investment in equipment, materials, and expertise is what separates a coating that lasts decades from one that fails in months. At Epoxy Designs, we never cut corners on preparation because we know it is the foundation of every floor we install.

Trust the Process

When you invest in a professional epoxy floor, the preparation phase may seem like the longest and most intensive part of the project. That is because it is — and it should be. Every hour spent properly grinding, testing, repairing, and cleaning the concrete translates directly into years of reliable coating performance.

If a contractor skips preparation, rushes through it, or uses shortcuts like acid etching, the risk of failure increases dramatically. When evaluating epoxy flooring contractors, ask about their preparation process. A reputable installer will be happy to explain every step because they know it is the most important part of what they do.

Contact Epoxy Designs for a free consultation. We will inspect your concrete, explain our preparation process, and give you confidence that your floor is being built on a solid foundation.