Why Flooring Selection Matters

Choosing the right flooring system is one of the most important decisions for any residential, commercial, or industrial space. The floor is the most heavily used surface in any building — it endures foot traffic, equipment loads, chemical exposure, and constant wear. A poorly chosen floor can lead to premature failure, costly repairs, and safety hazards. A well-chosen system delivers years of reliable performance with minimal maintenance.

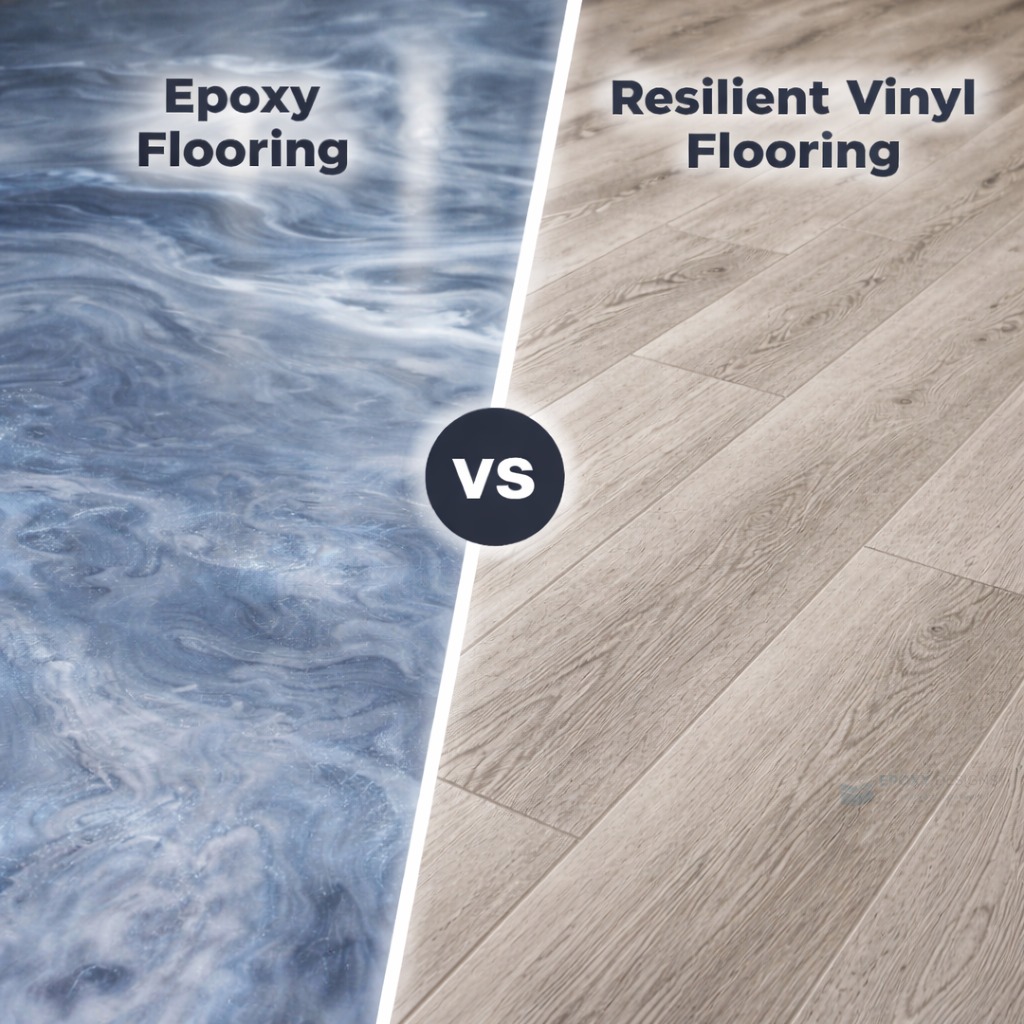

When evaluating flooring options, most property owners compare epoxy flooring against traditional materials like ceramic tile, hardwood, vinyl, and polished concrete. Each has strengths and limitations, but understanding the key differences in durability, maintenance, cost, and performance helps narrow the decision.

Epoxy Flooring: Strength and Versatility

Epoxy flooring is a resinous coating system applied directly over concrete substrates. It consists of a two-part chemical compound — a resin and a hardener — that bonds to the slab to create a seamless, high-performance surface. Epoxy coatings are available in a wide range of systems including solid-color (neat), decorative flake, quartz broadcast, and metallic finishes.

One of the most significant advantages of epoxy is its compressive strength. Professionally installed epoxy floors can withstand over 10,000 PSI, making them three times stronger than concrete alone. This strength, combined with chemical resistance, impact tolerance, and seamless coverage, makes epoxy the preferred choice for garages, warehouses, commercial kitchens, healthcare facilities, and manufacturing plants.

Epoxy floors are also highly customizable. Decorative systems like flake epoxy and metallic epoxy offer aesthetic appeal that rivals high-end tile or polished stone, while industrial systems like quartz broadcast and urethane cement provide extreme durability for demanding environments.

Ceramic Tile: Familiar but Limited

Ceramic and porcelain tile have been a go-to flooring option for decades. They offer a wide variety of colors, patterns, and textures, and they perform well in bathrooms, kitchens, and entryways. However, tile has notable drawbacks in high-performance applications.

Grout lines are the biggest weakness of tile flooring. Grout is porous and absorbs moisture, oils, and stains over time. In commercial or industrial settings, grout failure is one of the most common flooring problems. Cracked or deteriorated grout allows moisture intrusion beneath the tile, leading to delamination, mold growth, and structural damage.

Tile also lacks the impact resistance of epoxy. A dropped tool or heavy equipment load can crack individual tiles, requiring targeted repairs that may not match the original installation. In contrast, epoxy systems absorb impact across the entire surface without localized failure points.

Hardwood: Beautiful but Vulnerable

Hardwood flooring is prized for its natural beauty and warmth. It works well in residential living spaces and offices where aesthetics are the primary concern. However, hardwood is extremely vulnerable to moisture, chemicals, and abrasion.

In garages, basements, commercial kitchens, or any space where water, oil, or chemicals may contact the floor, hardwood is not a viable option. Even in residential settings, hardwood requires periodic refinishing, is susceptible to scratching, and can warp with humidity changes.

For property owners who want the look of natural materials with the protection of a resinous system, specialty wood coating epoxy systems offer a compelling alternative. These flexible epoxy formulations are engineered to move with wood substrates while providing a seamless, protective finish.

Polished Concrete: Simple but Unprotected

Polished concrete has gained popularity in modern commercial and residential spaces for its clean, industrial aesthetic. The process involves mechanically grinding the concrete surface to a smooth, reflective finish. While visually appealing, polished concrete lacks the protective qualities of a resinous coating.

Polished concrete is still porous and susceptible to staining from oils, chemicals, and water. It provides no additional chemical resistance or impact protection beyond the base concrete slab. Over time, polished concrete can develop micro-fractures, surface wear patterns, and discoloration in high-traffic areas.

Sealed concrete systems bridge the gap between polished concrete and full-build epoxy by applying penetrating or film-forming sealers that protect the slab while preserving its natural appearance. For spaces that want the concrete look with added protection, sealed concrete is often the better choice.

Cost Comparison

When comparing costs, epoxy flooring often delivers the best long-term value despite having a moderate upfront investment. Here is a general comparison:

Over a 10–15 year period, epoxy flooring typically costs less than tile or hardwood when factoring in maintenance, repairs, and replacement cycles. The seamless, non-porous surface eliminates grout maintenance, reduces cleaning costs, and prevents moisture-related damage.

Which Is Right for You?

The best flooring choice depends on the specific demands of your space. For garages, basements, commercial kitchens, warehouses, and industrial facilities, epoxy flooring is almost always the superior option. It delivers unmatched durability, chemical resistance, and long-term value.

For purely aesthetic residential applications where heavy-duty performance is not required, hardwood or tile may still be appropriate — though epoxy systems like metallic and decorative flake now rival these materials in visual appeal while offering far greater protection.

If you are evaluating flooring options for your home or business in New England, contact Epoxy Designs for a free consultation. We will assess your space, discuss your goals, and recommend the right flooring system for your needs.