The World of Epoxy Floor Coatings

Epoxy flooring is not a single product — it is a broad category of resinous coating systems, each engineered for specific performance characteristics and applications. Understanding the differences between these systems is essential for selecting the right one for your project, whether it is a residential garage, a commercial showroom, or an industrial manufacturing floor.

All epoxy floor coatings share a common foundation: they are two-component systems consisting of a resin and a hardener that chemically react to form a rigid, protective surface. Beyond this shared chemistry, the systems diverge significantly in terms of thickness, texture, decorative potential, chemical resistance, and intended application.

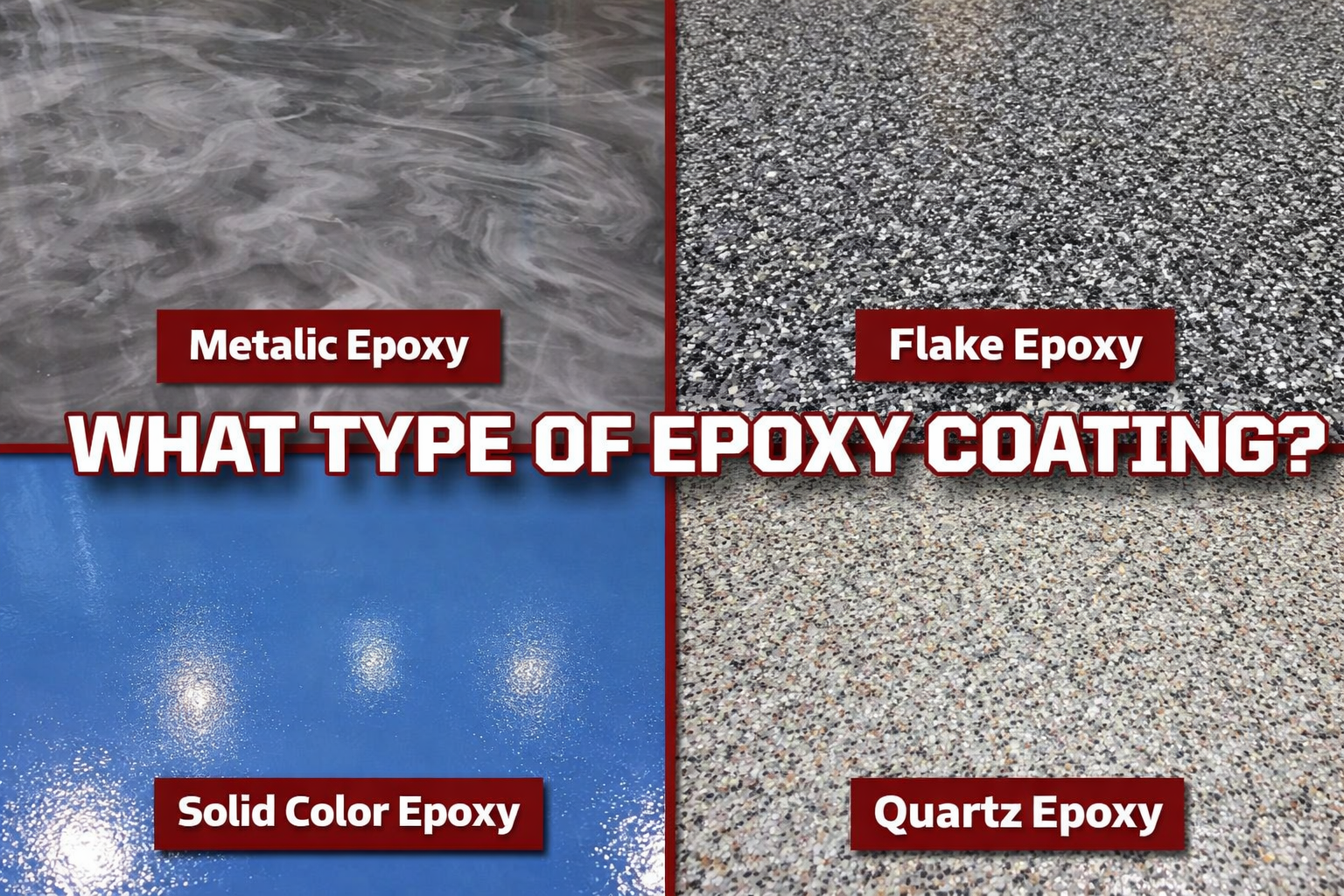

Neat (Solid-Color) Epoxy

Neat epoxy, also called solid-color epoxy, is the most straightforward coating system. It consists of a primer and one or more body coats of pigmented epoxy applied without decorative aggregates like flakes or quartz. The result is a smooth, uniform, single-color surface.

Best for: Warehouses, mechanical rooms, storage facilities, utility areas, and garages where performance and simplicity are prioritized over decorative appeal.

Advantages: Cost-effective, excellent chemical and abrasion resistance, seamless surface, easy to maintain, improves light reflectivity.

Considerations: Does not provide inherent texture or slip resistance without additives. The smooth surface, while easy to clean, may require anti-slip aggregates in wet environments.

Decorative Flake Epoxy

Flake epoxy is the most popular residential and light commercial system. During installation, colored vinyl or acrylic flakes are broadcast into the wet epoxy base coat. The flakes are then encapsulated with clear topcoats to create a textured, multi-colored surface.

Best for: Residential garages, basements, laundry rooms, showrooms, retail spaces, and any area where both aesthetics and durability are important.

Advantages: Hides concrete imperfections, provides built-in texture and slip resistance, available in virtually unlimited color combinations, durable and easy to maintain.

Considerations: The texture of flake floors can make them slightly more difficult to sweep clean compared to smooth systems. Heavy flake broadcasts create more texture than partial broadcasts.

Quartz Broadcast Epoxy

Quartz broadcast systems use colored quartz aggregate instead of vinyl flakes. The quartz is broadcast into the epoxy base coat and sealed with multiple topcoats. Quartz systems are thicker and more abrasion-resistant than flake systems.

Best for: Commercial kitchens, restrooms, locker rooms, pool decks, hospitals, schools, retail spaces, and areas requiring exceptional slip resistance and durability.

Advantages: Superior slip resistance, excellent abrasion and impact resistance, meets health code requirements for food service and healthcare, available in multiple color blends.

Considerations: Higher cost than flake systems due to material thickness and labor. The textured surface, while excellent for safety, requires more effort to deep clean.

Metallic Epoxy

Metallic epoxy uses specialized metallic pigments that create flowing, three-dimensional visual effects within the coating. Each installation is unique — the pigments are manipulated during application to create swirling, marbled, or lava-like patterns with a high-gloss, reflective finish.

Best for: Residential spaces, showrooms, retail environments, restaurants, lobbies, and any space where a premium, one-of-a-kind aesthetic is desired.

Advantages: Stunning visual impact, completely unique patterns, high-gloss reflective finish, seamless surface, strong chemical and abrasion resistance.

Considerations: Higher cost than standard systems. Requires skilled installation — the visual result depends heavily on the installer's technique. The smooth, glossy surface may require slip-resistant additives in wet areas.

Sand Broadcast Epoxy

Sand broadcast systems use silica sand aggregate to create a highly textured, industrial-grade surface. The sand is broadcast into the epoxy base and sealed with topcoats. These systems prioritize function and safety over decorative appeal.

Best for: Industrial facilities, manufacturing plants, loading docks, ramps, mechanical rooms, and any environment where maximum slip resistance and durability are critical.

Advantages: Excellent slip resistance even when wet, extreme abrasion durability, high load-bearing capacity, cost-effective for large industrial areas.

Considerations: The aggressive texture is functional but not decorative. The rough surface can be harder on the feet for workers standing for long periods.

Slurry Epoxy

Slurry systems combine epoxy resin with graded aggregate to create a trowel-applied mortar. The slurry is spread across the floor to build significant thickness — often 1/4 inch or more — creating an extremely robust surface that can handle the most demanding conditions.

Best for: Heavy industrial facilities, chemical processing plants, food and beverage production, areas with extreme mechanical and chemical exposure.

Advantages: Exceptional thickness and durability, superior chemical resistance, can level minor surface defects, withstands heavy machinery and forklift traffic.

Considerations: Higher cost and longer installation time due to material and labor requirements. Not typically used in residential or light commercial applications.

Specialty Systems

Beyond the standard systems above, several specialty epoxy formulations address unique requirements:

Urethane Cement

A hybrid system combining urethane and cementitious technology. Urethane cement floors offer extreme thermal shock resistance, chemical resistance, and can be installed at temperatures as low as freezing. They are the go-to system for commercial kitchens, breweries, food processing plants, and cold storage facilities.

ESD (Electrostatic Dissipative) Epoxy

Engineered to safely dissipate static electricity to ground. ESD epoxy systems incorporate conductive primers and copper grounding grids to maintain electrical resistance within a specific range. Essential for electronics manufacturing, data centers, server rooms, and ammunition facilities.

Sealed Concrete

Not technically an epoxy system, but often discussed alongside them. Sealed concrete uses penetrating or film-forming sealers to protect the slab while preserving its natural appearance. Ideal for spaces that want a modern, industrial look with basic protection.

Wood Coatings

Flexible epoxy systems engineered for wood substrates. These coatings have enhanced elongation properties that allow them to move with the natural expansion and contraction of wood without cracking or delaminating.

Epoxy Cove Base

A wall-to-floor transition system that creates a seamless, radiused cove at the base of walls. Cove base eliminates the gap between the floor and wall where dirt, moisture, and bacteria accumulate. Required in many food service and healthcare environments.

How to Choose the Right System

Selecting the right epoxy system comes down to four key factors:

1. Environment: What will the floor endure? Foot traffic, vehicles, chemicals, thermal shock, static electricity?

2. Aesthetics: Does the floor need to look decorative, or is function the priority?

3. Budget: What is the available budget for materials and installation?

4. Longevity: How long does the floor need to last before maintenance or replacement?

A professional flooring contractor can evaluate your space and recommend the optimal system based on these factors. At Epoxy Designs, we offer free consultations to help you navigate the options and make an informed decision for your residential, commercial, or industrial project.